FAQ

Open Play Store and search for "Shyam Steel Apna Ghar" and install the app. After installation process is done, open it and allow all the required permissions. After it, provide your right credentials for login or sign up if you are a new user.

This gives you the estimated required material quantity as per your requirements(According to total number of floors)

Click on Shop Online and then add products to cart and open it. Now click on proceed. Then click on "Select your side" and choose "Add new site" from the dropdown menu. Now enter right credentials in the required fields and create any IHB Project of your desire and take a step forward toward building your dream house.

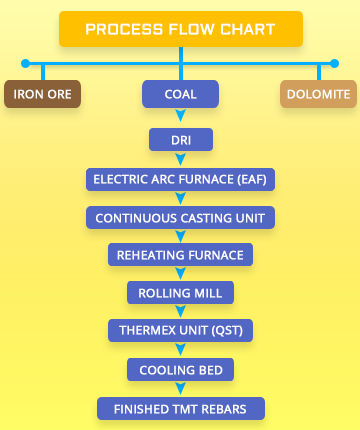

Shyam Steel 500D is made out of pure iron ore using best of the steel making processes as per IS 1786:2008, ensuring best quality. It goes through 10 types of quality checks and thus there is no compromise on quality.

Properties of Shyam Steel TMT Re-bars

- Flexible steel which absorbs the seismic impact during Earthquake.

- Uniform strength across the length of rebar.

- Constant diameter across the length of rebar.

- Superior ductility with soft inner core and hard outer layer.

- High bonding with concrete.

- Even rib pattern throughout the rebar length.

- Lowest impurities resulting in higher strength & ductility.

- Primary steel is produced through integrated process in a single premise from Iron Ore/Pellet resulting in better and consistent quality.

- Secondary steel is produced via secondary route with scrap/ingot and thus quality of steel in uncontrolled.

Generally for construction of one floor including foundation, steel requirement is approx. 4 Kg/sq. ft. of construction. Thus for 1000 sq. ft. of built up area of construction, steel requirement will be approx. 4000 Kg.

Generally for construction of one floor, the required cement quantity is approx. 450 sacks.

We should always use mixed aggregate (I.e. 5/8 + 3/4 mixture), this will make the concrete more dense and impermeable. Generally in the language of contractors, we should go for downgraded aggregate instead of pure aggregate.

We should always use the type of sand that has a very low silt content. Generally we should sieve the sand at the site to remove the silt content and then use it for better concreting.

We should always control the water-cement ratio which plays the most important role in imparting durability and strength to the concrete, it is recommend to add 24-25L of water in one sack of cement used in concreting.

As per IS 456, nominal mix should be M20 i.e. Cement (1) : Sand (1.5) : Aggregate (3) portion.

It should be pure, potable water free from all types of salt and impurities.

Generally curing of 10-12 days is must in a residential building (the duration will increase for longer spans).

Cement consumes (12-14)% of the total cost, as well as steel consumes (8-12)%, sand (4-5)%, aggregate (4-6)%, bricks (8-10)% and labor (7-10)%.

Bricks having definite size, shape and also the Bricks which produce metallic sounds when two of them are clashed with each other.

Both Fe500 and Fe500 D are supposed to offer a minimum of 500 MPa of Yield Strength (YS), where they differ is the ductility parameter. Fe500 D grade offers higher ductility (measured as UTS-YS ratio & percent elongation) than Fe500 rebars due to lower impurities like sulphur and phosphorus. Ductility is critical for the performance of rebar within a structure especially during extreme loading conditions (like earthquakes).